Capacity Planning in Manufacturing Industry

New product development leverages data to improve quality and profitability and reduce time-to-market and. Industry 40 is bringing about the convergence of information technology IT and operational technology OT systems creating interconnectivity between autonomous manufacturing equipment and broader computer systems.

What Is Capacity Planning Strategies Tools And Process

From the 2021 to 2022 academic year onwards we are keen to ensure that CDF delivery facilitates sufficient capacity building for industry placements across relevant programme areas as we roll out.

. There are many software solutions offered for manufacturing resource planning. OT data from sensors PLCs and SCADA systems is being integrated with IT data from MES and ERP systems. Most are expensive though they offer a free trial.

Make to Stock MTS Make to Stock is common within discreet manufacturing and process manufacturing. Material requirements planning MRP is a production planning scheduling and inventory control system used to manage manufacturing processes. But this is the trajectory for US manufacturing in 2022 emerging from the pandemic.

The deal struck just weeks ago will allow Shein to expand its flight capacity and warehousing resources while reportedly allowing for more shipments to the US and Europe. The move is designed to foster resource sharing. An MRP integrates data from production schedules with that from inventory and the bill of materials BOM to calculate purchasing and shipping schedules for the parts or components required to build a product.

Ensure raw materials are available for production and products are available. Augmented by machine learning. Packaging and manufacturing processes.

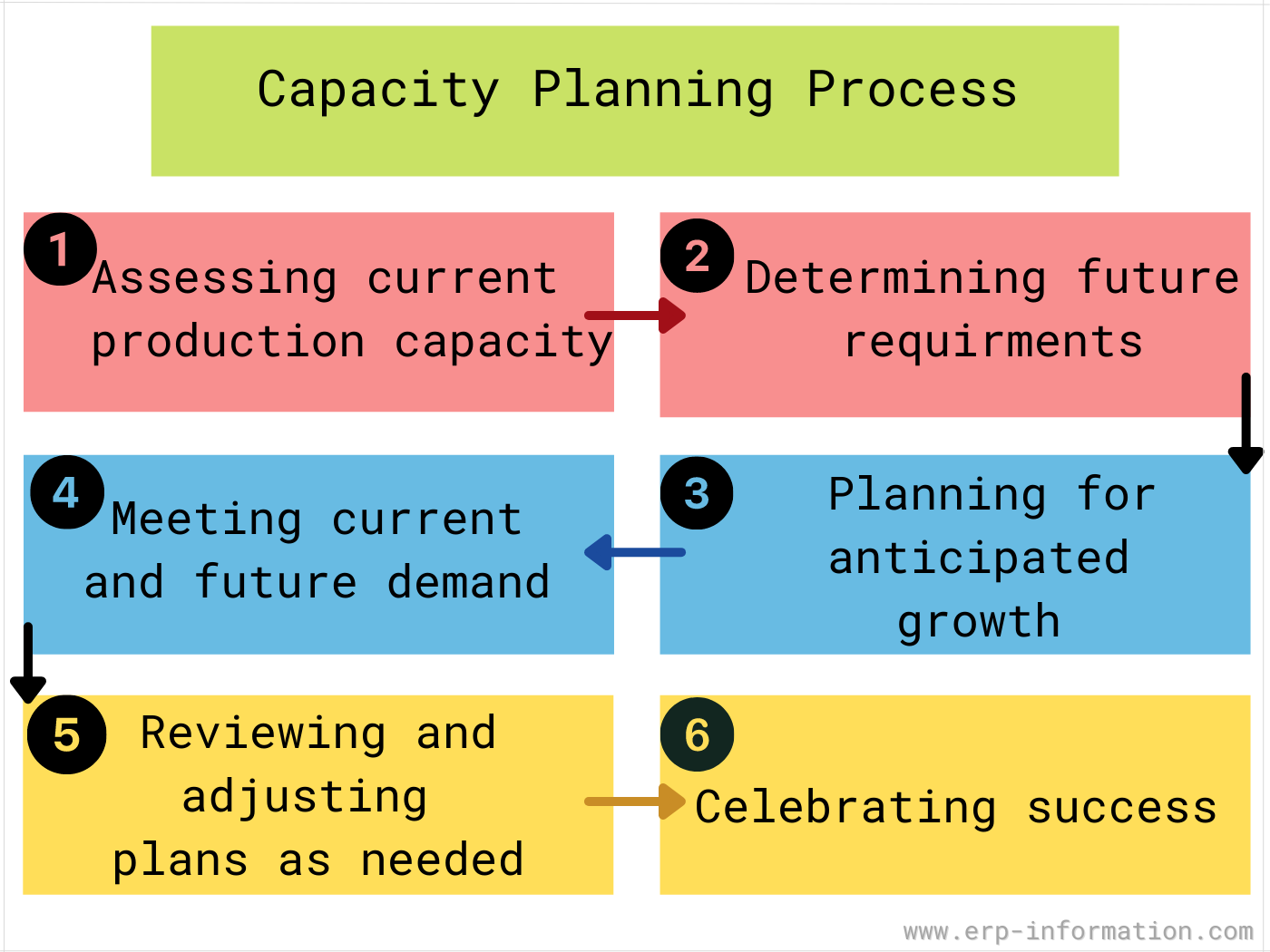

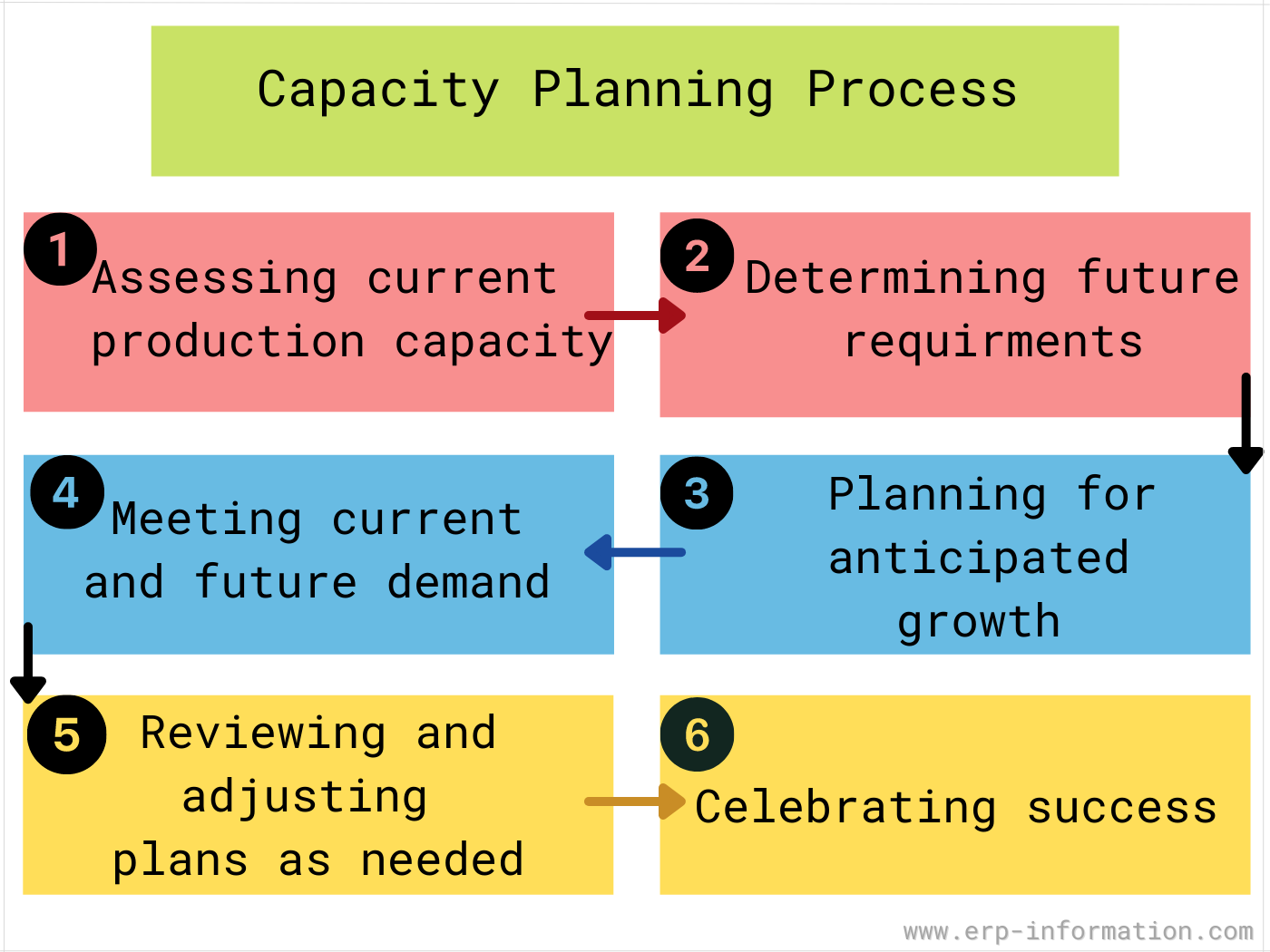

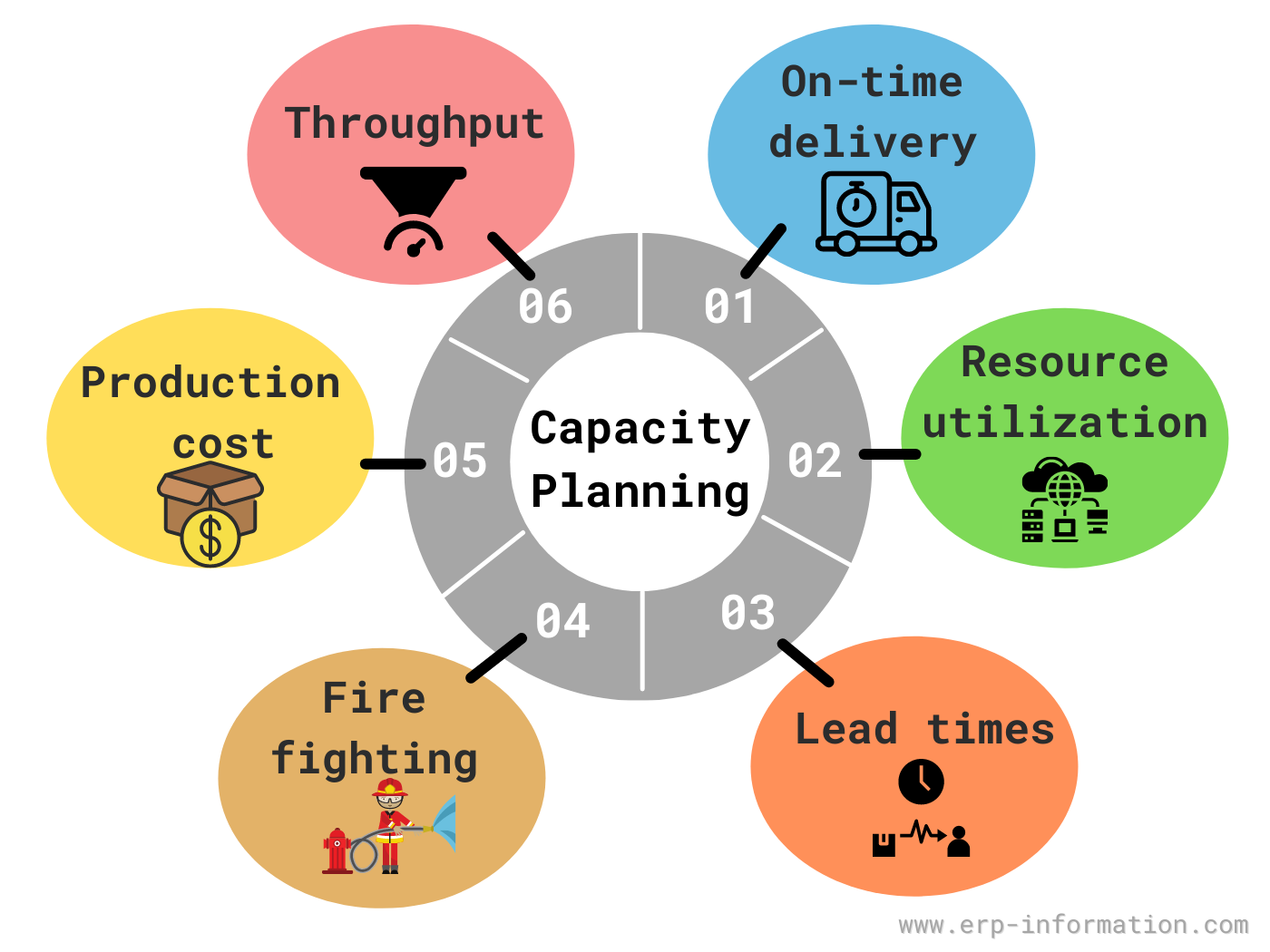

Most MRP systems are software-based but it is possible to conduct MRP by hand as well. Capacity planning means knowing the maximum capacity your operation can managethe absolute most of a product or service it can offer during a period of time. Contact Us 1155 Gratiot Avenue.

Practical examples of models in capacity planning for different production modes include. While this is a workable solution that. Capacity planning and techniques will function differently depending on production mode.

The tools run the gamut from Windows only to being able. Optimize planning with accurate forecasting and reporting that contributes to your bottom line. Explore Industry Electronics Semiconductors.

Fast fashion retailer Shein is looking to boost its logistics capacity through a partnership with China Southern Airlines Logistics CSAL. This two-step iterative process can be time consuming. Planning can be executed in finite or infinite capacity mode and planning time periods can be days weeks months or a combination of all three.

Industry 40which includes connectivity advanced analytics automation and advanced-manufacturing technologies Exhibit 1was gaining momentum before COVID-19 helping companies transform their operations in everything from production efficiency to product customization with improvements in speed to market service effectiveness and new-business. Our solutions bridge the gap between the virtual and physical worlds to help our customers get ahead of the competition. Material requirements planning MRP is a production planning and inventory control system.

This is the only way to anticipate how much of each resource you will need in order to create X amount of products. Advanced Scheduling functionality considers the availability of resources and additional constraints such as tooling and materials to ensure an accurate model of the manufacturing environment. The recovery gained momentum in 2021 on the heels of vaccine rollout and rising demand.

The Automotive News mission is to be the primary source of industry news data and understanding for the industrys decision-makers interested in North America. Opcenter APS is a family of production planning and scheduling software products that help you better orchestrate manufacturing processes. 2022 manufacturing industry outlook Manufacturers eyeing growth It is unusual to see positive economic indicators paired with historic labor and supply chain challenges.

As these operations often have complex multi-level BOMs. The Digital Thread for Industry 40. We believe that when engineering manufacturing and supply chain work together companies outperform at every level.

Connect and synchronize your product manufacturing and distribution activity to streamline communication. With traditional MRP the material plan must be validated against capacity using a separate capacity planning tool. An MRP system is intended to simultaneously meet three objectives.

The manufacturing resource planning of the 1970s has advanced to include much of these features and is now referred to as manufacturing resource planning II. When you dont know the production capacity your production planning is like taking. Request a Demo Today Plex Systems joins Rockwell at the perfect time as more customers are starting to move their industrial.

Examples of capacity constraints include production resources like ovens or painting lines tooling or specially trained technicians.

Production Capacity Calculation Template Capacity Planning Capacity Historical Data

Role Of The Sam Value In Production Planning And Control How To Plan Sewing School Change Management

What Is Capacity Planning Strategies Tools And Process

Best Manufacturing Planning Software For Manufacturing In 2021 How To Plan Planning Maps Capacity Planning

Comments

Post a Comment